Minitab upgrades their software to new versions periodically, so the look of the DOE wizards may be slightly different depending upon which version you are using. There will be additional Minitab lessons in the next section, so carefully plan when you want to start your trial.

DOE MINITAB TRIAL

Minitab provides a free 30 day trial so you can use this application to complete this lesson. It is widely used in the Lean Six Sigma community. Minitab is a commercially available statistical analysis software application.

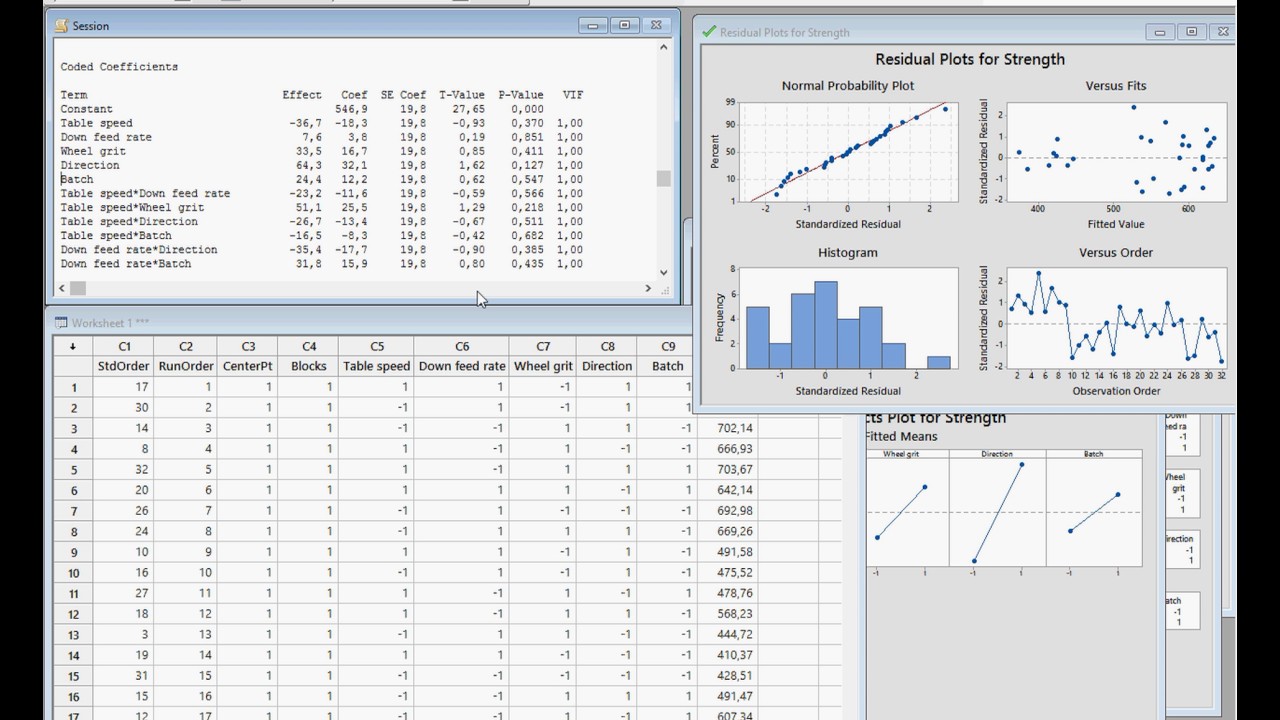

For that reason, the software is especially helpful with large and complex studies. The use of a statistical software application to plan and analyze a DOE will simplify the process for the study team. The Minitab application is a popular application often used with Lean Six Sigma projects and it has wizards that will plan and analyze DOE studies. It has provided a solid knowledge base about Lean in a short space of time and also given me more confidence to challenge ways of doing things in our factories as we strive for customer delight and continuous improvement.Statistical software applications are often used when doing Design of Experiments studies. All assignments were linked to the 8 step problem solving model we were studying and I was able to build and develop my own A3 document over the course of the sessions, just like real life in the factory!Īs someone who came from a commercial background into manufacturing, I have found this learning invaluable. Over the course of the tutorials we covered areas like 5s, 7 wastes, Gemba visits, spaghetti mapping, 5 Whys & fishbone, Failure Modes & Effects Analysis (FMEA), SMED and OEE.Ĭourse delivery was via a weekly 90 min Google hangouts session, we had plenty of time for discussion and I got a weekly assignment to complete for the following week’s tutorial. “Great course that gave me an overview of Lean and its origins, we focused the tutorials on the Toyota 8 Step problem solving model and worked through live examples for each step. A foundation webinar can be arranged for those who need a grounding in statistics before the course commences. Prior to participating, participants should have a basic knowledge of statistics. In summary, this approach is useful to anyone charged with optimizing the performance of a process that has many input variables. DOE is also particularly useful for the development of new analytical tests and methods.

DOE MINITAB SERIES

This series of online DOE webinars is designed for product or process development chemists, engineers, scientists and statisticians in all industries and services including pharmaceutical, medical, automotive, general engineering, semiconductor, plastics and composites.

DOE MINITAB DOWNLOAD

The course content is customised to meet the organisation’s need, at no extra cost. All Lean Ireland online tutors are certified Lean Six Sigma black belts with several years’ experience in facilitating online workshops in a wide variety of sectors.Ĭall us on +353 91 870708, we’re always happy to help and to discuss our courses in more detail. all candidates are from the one organisation. This course is offered on an in-company basis only i.e. This build confidence in designing and executing a DOE using the online simulation tool. In addition to the contact hours on webinars, participants are required to work on small assignments between modules. Total contact hours = 16 hours for all 4 webinars. In addition to an online simulation tool, detailed case studies and interactive Q&A are used to deepen student learning. The course covers factor selection, experiment design and execution, and visual statistical analysis using Minitab. To enhance participants learning, use is made of an online DOE simulation tool. The software application used is Minitab. The focus is on the practical application of this essential product and process development tool. This series of four interactive webinars introduces DOE to development chemists, engineers, managers, and technicians. DOE enables the selection of optimal settings for these inputs in order to optimize process outputs. temp, pressure, time, altitude, colour, material type) have most influence on the process outputs. Design of Experiments (DOE) is an approach to process design and analysis that identifies which input factors in a process (e.g.

0 kommentar(er)

0 kommentar(er)